Maximize separation performance, minimize operating expenditure with smart measuring technologies

Oil and gas separators are mechanical devices that divide oil, gas and water from a well stream. They come in various sizes and configurations, such as two-phase (oil and gas) or three-phase (oil, gas and water) and in vertical or horizontal orientations. Enhance efficiency and ensure compliance in your separation processes:

- Simplicity by design and use to achieve operational excellence

- Accurate measurement of well fluids allowing the operators to minimize environmental impact and informed decision making

- Smart diagnostics and remote verification ensure high availability

Dynamic Installed Base Analysis

Expert recommendations with frequent insights to improve the lifecycle management of your measuring instruments, ensure plant safety and process reliability.

- Increase your process availability without compromising on meeting regulation requirements through professional advisory guidance

- Maintain control over your instrumentation and reliability with a continuous evaluation of your instruments’ maintainability

- Increase your asset reliability with the tracking of your obsolescence status and availability of most critical spare parts

- Improve the sustainability of your operations by benefiting from regular optimization advices provided by our service consultant.

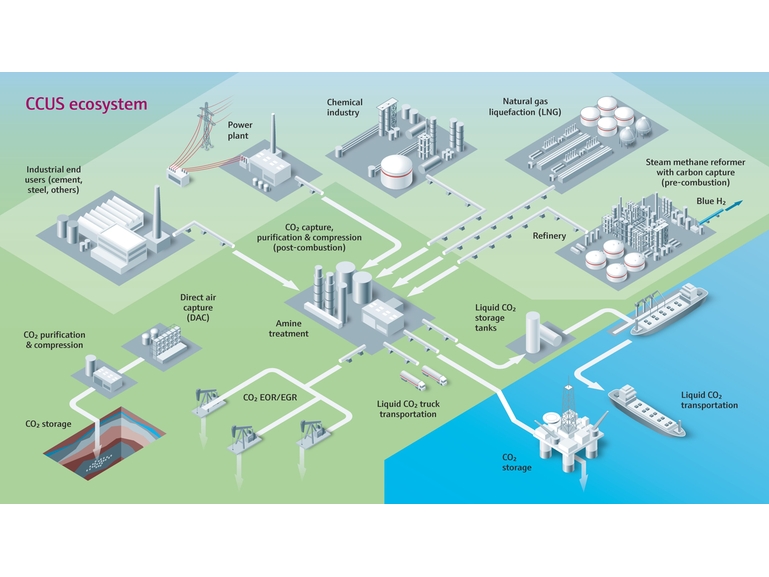

Enhance safety and efficiency when measuring CO2 streams

We have launched a series of new products for the Oil & Gas industry that help you to measure critical parameters in the carbon capture value chain accurately and reliably. Our mission is to help you meet your industry goals through:

- Traceable quantitative measurements according to industry and metrology standards

- Reliable quality measurements to verify the CO2 stream meets the transport and storage regulation requirements

- With our expertise and decades of experience, we can guide and support customers on important project milestones during planning and execution phases

CO2 flow metering solution

Accurately measuring the flow rate of CO2 in a dense or supercritical phase is a key application in long-distance pipeline transportation. From design to on-site installation, we have the know-how to execute these complex CO2 flow measurements while fulfilling regulatory quantity and quality parameters with a fit-for-purpose portfolio of flow, pressure, temperature, and gas analyzers.

- Coriolis mass flow meters ensure highest accuracy and repeatability

- Complete metering skid suitable for continuous operation at high pressure

- Laser based analyzer (TDLAS) to ensure the quality of CO2 by measuring impurities

Increase safety and increased reliability for your LNG regasification process

Natural gas and LNG are gaining momentum as low-carbon fuels - safe processing has never been more vital. Our range of new products and solutions maximize safety and efficiency in the regasification process while reducing maintenance efforts through:

- Traceable quantitative measurement that enables custody-transfer-proof flow measurement with accurate, quality and composition measurement, resulting in reliable calorific value in real time

- Innovative design: Smart integration of measurement and safety components to improve reliability and transparency

- Solution capabilities: Endress+Hauser is an experienced partner for successful project execution and implementation according to international standards

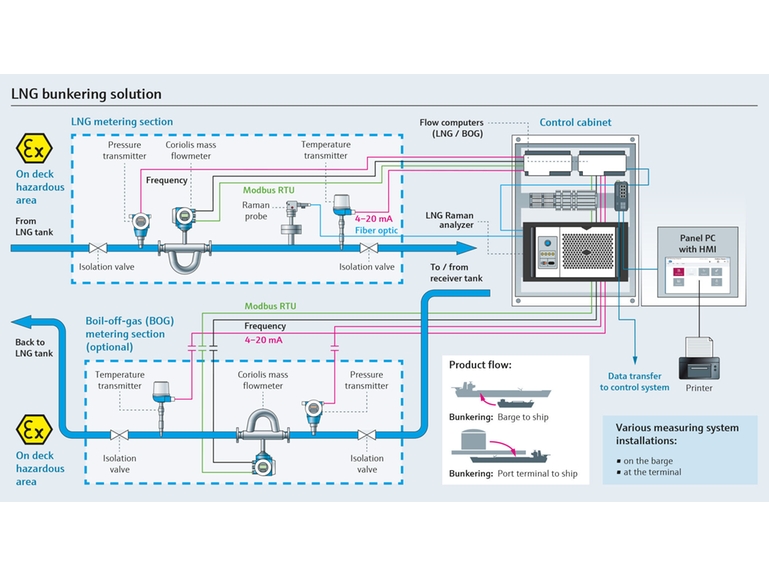

LNG bunkering solution

Our LNG bunkering solution provides real-time metering and composition analysis. This solution maintains safe and efficient bunkering operations on and offshore for various vessels. It provides:

- Highest accuracy from Coriolis flowmeters with direct mass measurement; no complex tank gauging calculations needed

- Composition monitoring in real-time with patented Raman technology

- Overall operating costs are reduced due to low maintenance

- Compliance with international standards

Smart Support

Direct access to Endress+Hauser expertise through our online knowledge base and remote support sessions with technical engineers who ensure availability and prompt response times.

- Maximize process availability and avoid costly downtimes

- Enhance plant and operator safety with minimized exposure to hazardous conditions

- Reduce unnecessary travel-related emissions to contribute to your sustainability and net zero targets

Deeper insights into process and instrumentation performance

Smart sensors collect real-time data from processes and monitor equipment and health, keeping you informed about product and asset performance. Digitizing production processes provides data visualization opportunities for personnel working with the process who typically do not have access to the data, creating data transparency. Endress+Hauser's Netilion can do just that, empowering end users to make the best decisions.